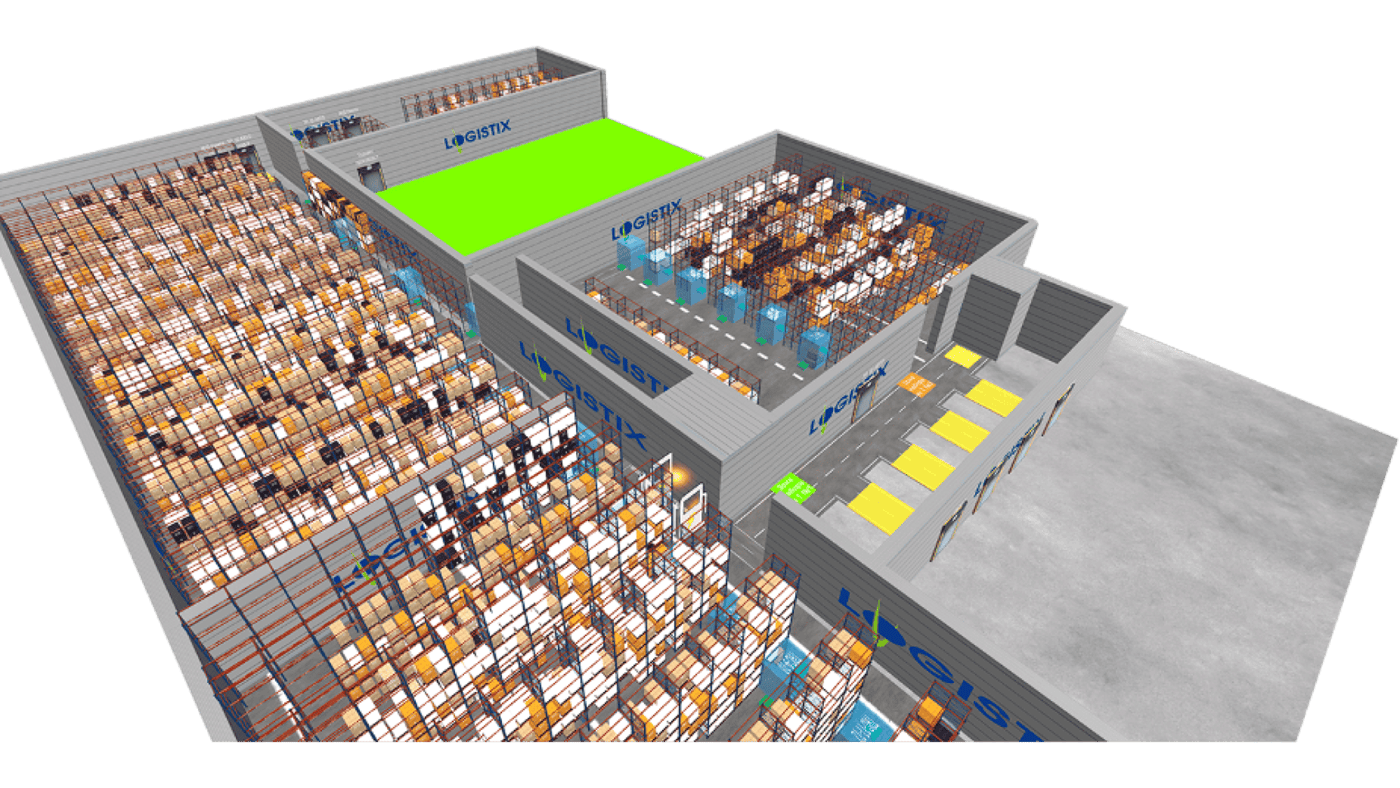

Design and test warehouse processes in a risk-free digital environment. LEAD SIM helps you validate decisions, eliminate bottlenecks, and optimize performance—before implementation. All through an easy-to-use, game-engine-powered 3D simulation platform. Ensure measurable results, avoid costly tech mistakes, and maximize ROI.

LEAD SIM integrates seamlessly with the LEAD ecosystem while providing sophisticated simulation capabilities that allow logistics professionals to validate improvement hypotheses without disrupting current operations.

LEAD SIM delivers comprehensive warehouse modeling capabilities with an intuitive interface that makes complex simulation accessible to logistics professionals.

Interactive graphical representation of material flows, bottlenecks, and resource utilization patterns reveals opportunities that remain hidden in static analysis.

Compare multiple operational strategies, equipment configurations, and staffing models to identify the optimal approach before capital investment.

Precise calculation of expected returns on technology investments including conveyors, AS/RS, AGVs, and robotics based on your actual operational data.

Forecast warehouse performance under varying demand conditions to ensure your facility can handle seasonal peaks and growth without service disruptions.

Verify ROI on automation equipment, conveyor systems, and robotics before purchase, avoiding expensive miscalculations in capital expenditure planning.

Compare performance impacts of different technologies (voice, RF scanners, pick-to-light, and etc.) to select solutions that best match your specific operational requirements.

Test multiple warehouse layouts and flow strategies to maximize space usage, reduce travel time, and boost throughput—without the cost of physical rearrangement.

Catch costly design flaws early. LEAD SIM simulates warehouse processes based on real product handling technologies and physical characteristics of goods and equipment, helping you avoid time and budget overruns later in the project.